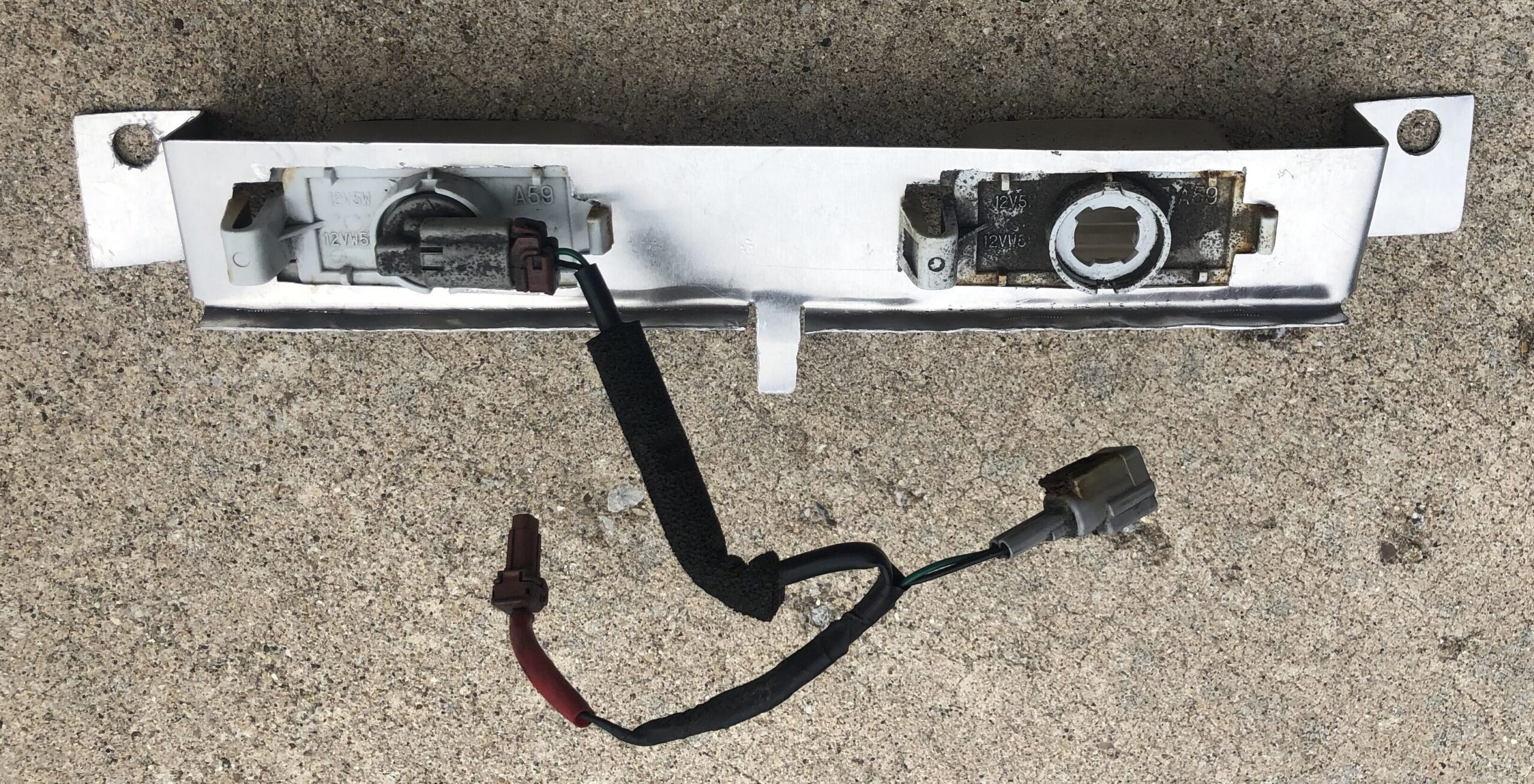

When i was changing lights in my car and went to reach for the license plate light, i just felt wires, then felt rusty metal crumble onto my hand. Then i pulled out this crap.

I tried to rig it up with zip ties and wire, but it didnt work, so i knew i had to fix it quick. I searched and found the part online for $50. I ordered it and when i got it i wasnt really surprised how simple of a part it is for $50, but i knew i could easily replicate the function out of scrap metal.

Since ive been wanting to practince with Solidworks Sheet metal, i figured this is perfect.

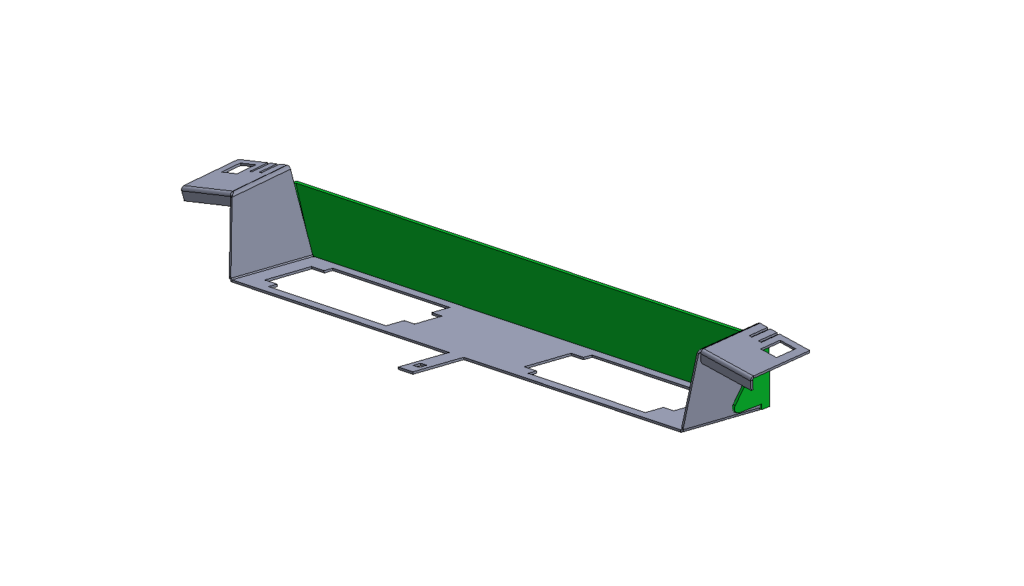

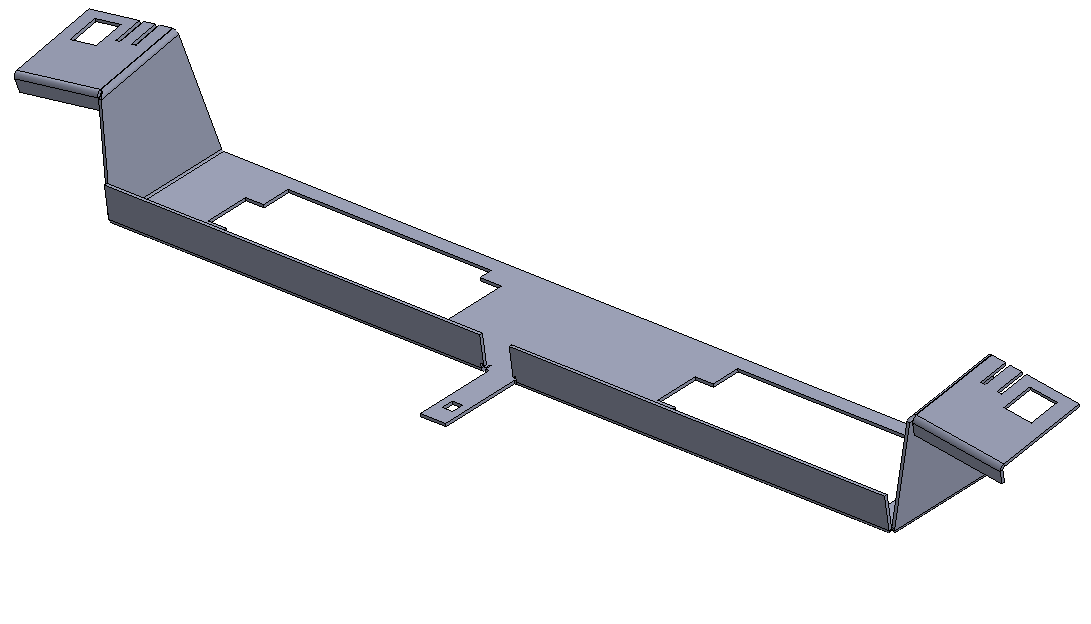

I started by modeling the purchased part in Saladworks. I noticed that it is made from two separate sheet metal parts, welded or sandwiched together.

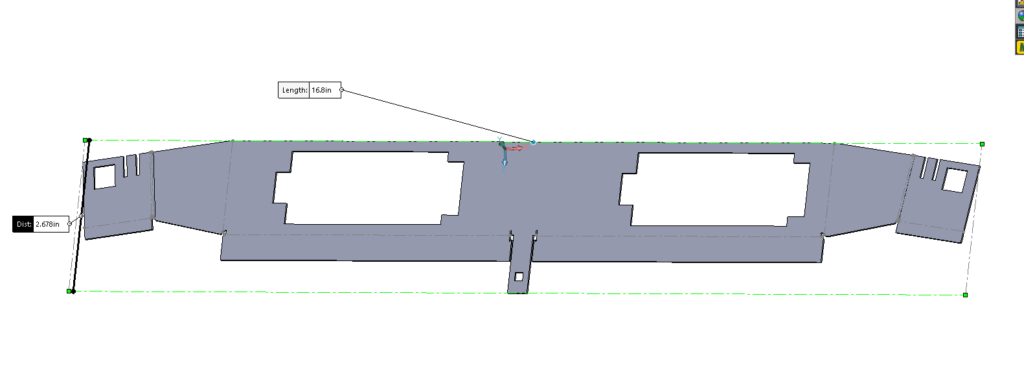

Next was to use the Sheet metal feature called “Flat Pattern” which converts a sheet metal part to a 2D layout that can then be cut and folded out of sheet to make the part

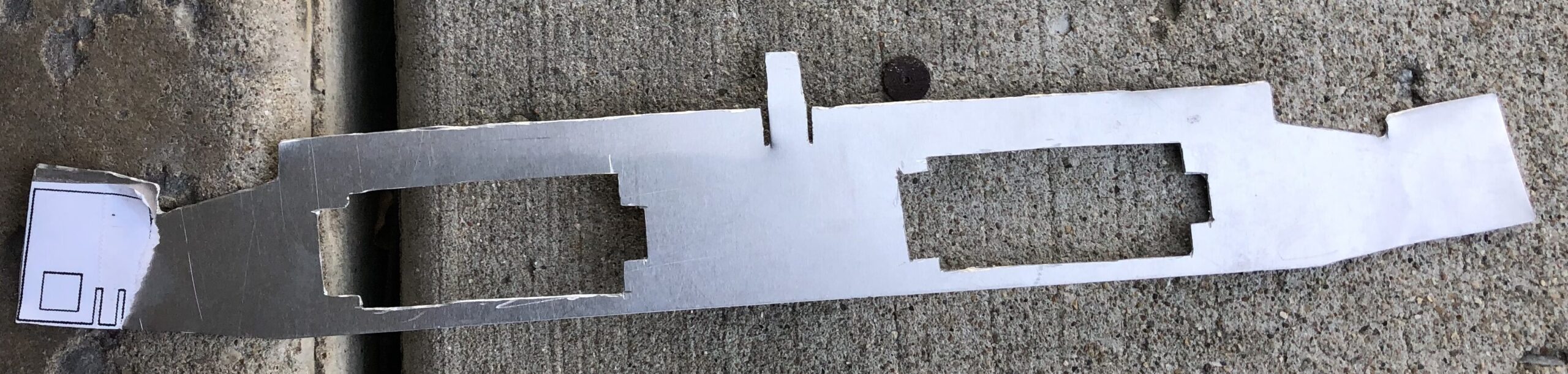

I Printed out the Flat Patter in real size. I cut it out and taped it on a sheet of aluminum. I started trying to cut it with shears, but it was kind of difficult, and i figured i would have to sand the edges and dremel out the pockets anyway. So i ditched the shears and just used a cut off wheel on the dremel to cut along the lines.

The Bending was not bad. The hardest part was the short long support ribs. They’re hard to get a grip on to fold, and its a big tab with a lot of aluminum. I made a smart move and did those first, since i would have a flat sheet to put in a vice and hold.

The part turned out great. It cost about 99% less than OEM. It fits and works prefectly.

Ask me any questions you may have or share what you want to see next!