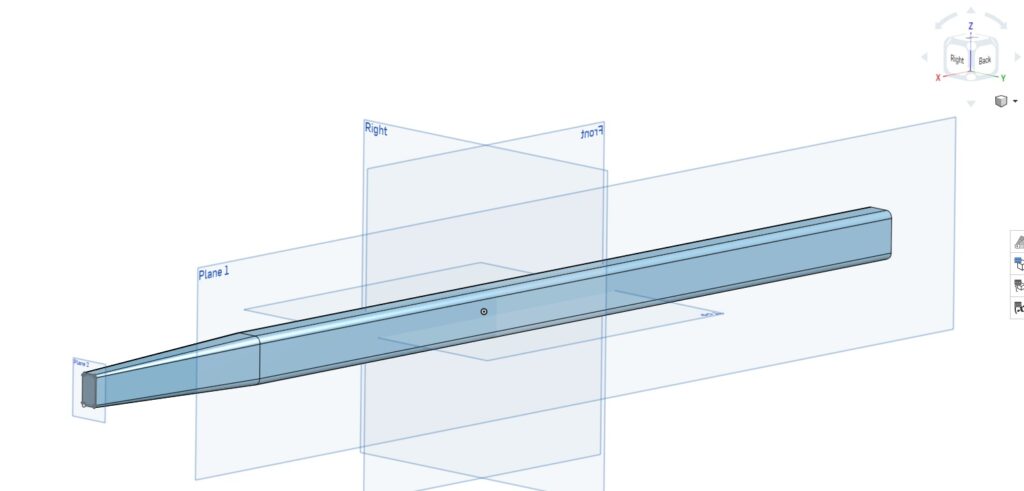

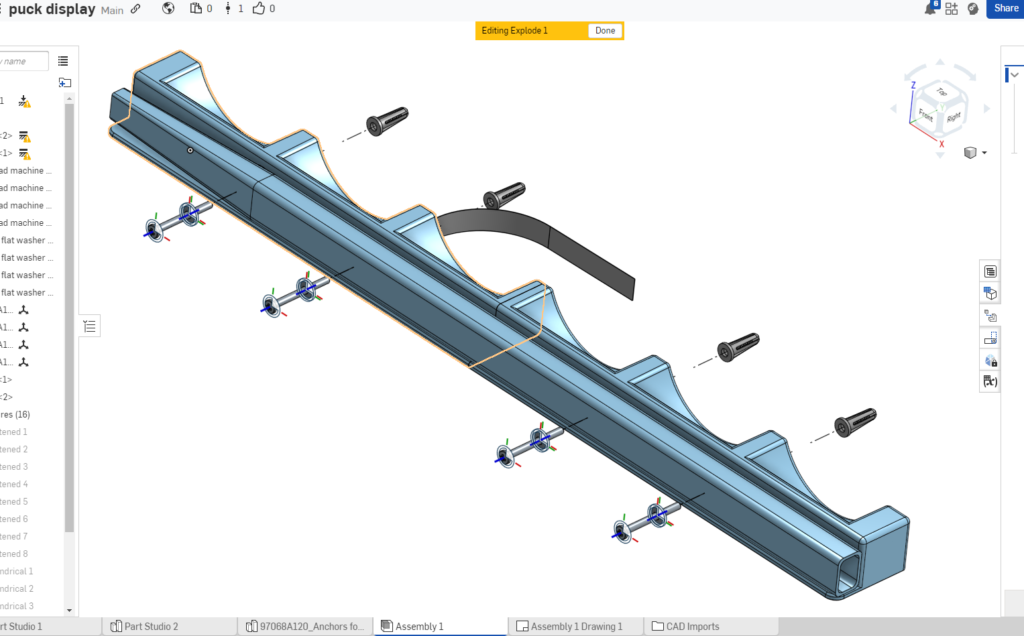

I kind of already had a good vision of how this project would go so I wanted to incorporate something new and challenging into it. I figured this is a good project to use a new software called OnShape that I’ve been eyeing.

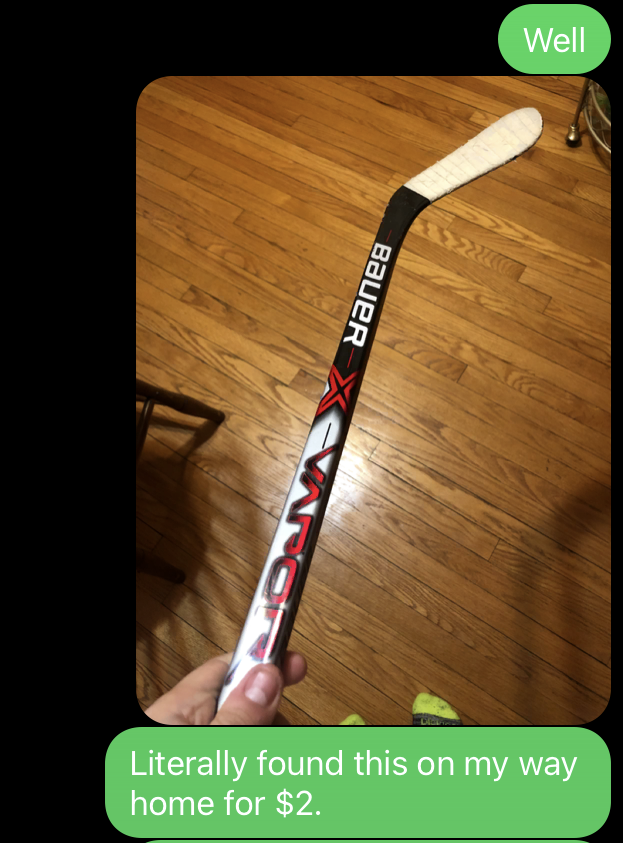

I started by cutting the blade off of the hockey stick so I would be left with the 20 inch shaft. Then I modeled that in OnShape.

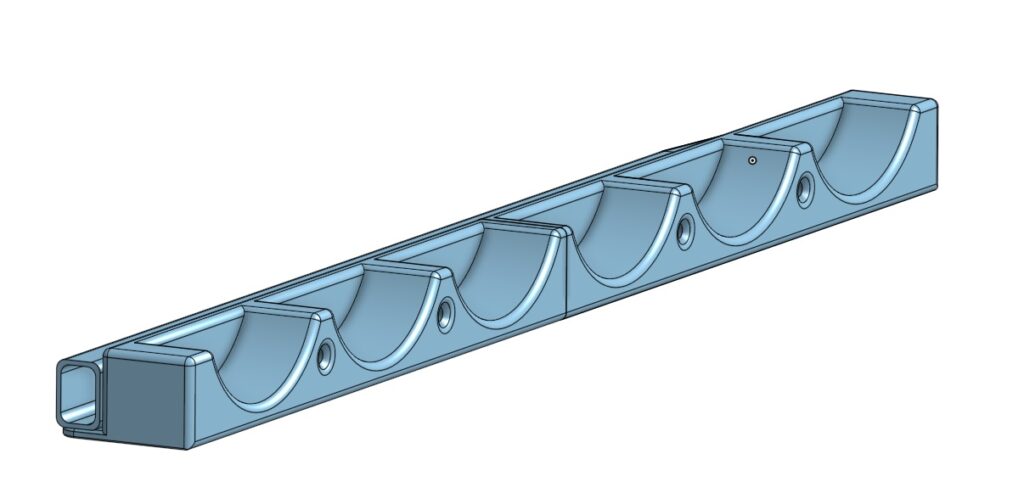

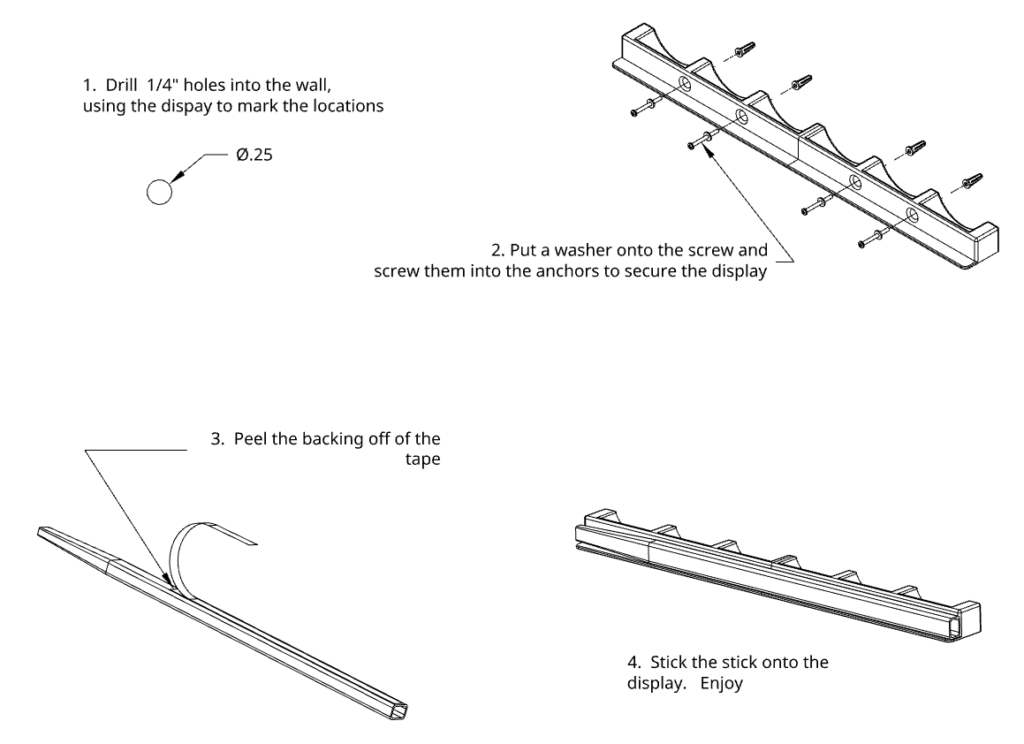

Now i can design a shelf that uses the shaft as a decoration. Since I couldn’t print a part that is the full 20″ length, i would have to make it in two halves.

Ask me any questions you may have or share what you want to see next!